Loading page header ... or Your browser does not support JavaScript

Back to "Tamara" Main page< Previous page = Next >

Building 'Tamara': |

|

|

|

| Yes,

its starting to look like a boat! Just a few more small plates at the

turn of the bilge and we will be ready to cast the lead into the keel. |

Of

course two plates had to be left out so the lead could be poured into each of

the keel compartments via a gutter leading from the melting

pot into the boat. The flames are from old engine oil burning on top of

the melt for added heat. |

|

|

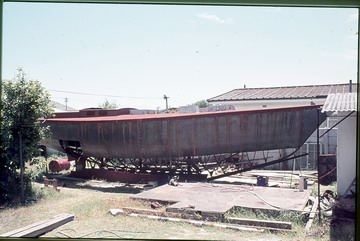

| The hull is closed up and after being in the ground for so long, the hull will now be lifted up to ground level. |

The gantry structure and three hoists in place ready for the lift. |

|

|

| Meantime the engine had been marinized and tested... |

The mast built and painted... |

|

|

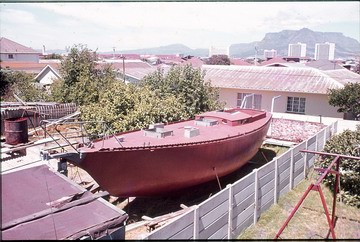

| She is out of the ground, the engine had a trial install and one can see the pulpit and davits in place. |

The hull was sand blasted to SA 2 1/2 and primed. |

|

|

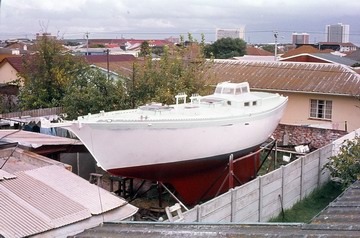

| Seven coats of primer paint were applied with an airless spray machine. Don't skimp on paint on a steel boat. |

The engine had been removed for the sandblasting and has to go back in again, here the temporary gantry has been set up for the task. |

|

|

| Finish coats done, she is just waiting for the dark green stripe.. |

Now everything is ready for the hauling out of the garden, but lets get back to what happened inside:- |

|

|

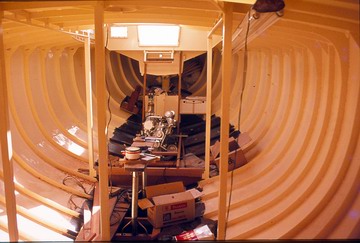

| The bilges were painted with two coats of coaltar epoxy and the rest had epoxy based primers applied

and many coats of enamel finish paints. After all a lot of it would be inaccessible once the joinery was done. |

The flatbar frames had been pre-drilled for the attachment of joinery. The engine is housed in a removable box containing the sinks and companion steps. |

< Previous page = Next >

Top of Page

Loading first page footer ... or Your browser does not support JavaScript

Loading second page footer ... or Your browser does not support JavaScript