Loading page header ... or Your browser does not support JavaScript

Back to "Alegra" Main page <> Next Building the 'Alegra':The "'Alegra'" is a 3.35 m (10' 11.8") plywood chine dinghy with a flat keel strake. She is constructed using the stitch and glue (or tack and tape) method and is assembled in a cradle. The complete port/starboard hull panels are made up on the bench prior to assembly. The inwales (inner gunwale), seat top stringers and floor stiffeners are glued on to the panels while on the bench. |

|

|

|

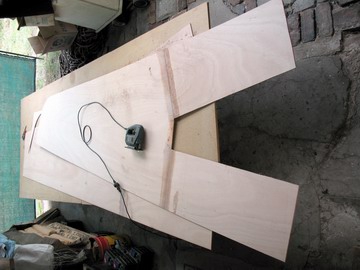

| Lofting hardboard patterns for hull panels. | One complete hull side is made up by butt joining extensions to a full size sheet of plywood. Butt joins are made by epoxy glassing inside and out. |

|

|

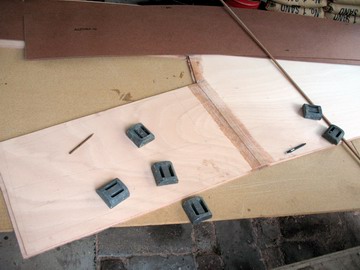

| Hardboard patterns being used to mark off hull panel shapes on one plywood blank. | Internal fitment lines transferred to plywood. |

|

|

| Ready to cut out one panel with jigsaw. | This panel is then used to make an exact copy by first drawing a line around and cutting out with a jigsaw to within a few millimeters, then using a router with flush trim bit. (the bearing runs on the finished panels edges) |

|

|

| Making up mid bulkhead halves. Radiused cutouts etc. are cut first with a circle cutting attachment on router. | Various bulkhead parts ready to assemble. |

|

|

| Transom with all solid wood parts glued on. | Completed mid-bulkhead/daggerboard case assembly. |

Top of Page

Loading first page footer ... or Your browser does not support JavaScript

Loading second page footer ... or Your browser does not support JavaScript