Loading page header ... or Your browser does not support JavaScript

Previous page <> Next

Building the 'Sinbad 2' kit - continued: |

|

|

|

| Daggerboard case spacers have been rough cut on the circular saw and here I am 'planing' them with the router. Two rails either side guide the router at a fixed height. | Spacers will be glued initially only to one case side, here the spacers are in the dry fit stage. |

|

|

| Moving to mid bulkheads. The slide-lock recess being routed. | The aft mid-bulkhead has a 70x22 stiffener glued to the top edge. |

|

|

| Then it requires a few vertical ribs and plywood doublers for the lock. (dry fit stage) | The CNC cut bolt holes are used for alignment and the doublers panel pinned to locate them during gluing. |

|

|

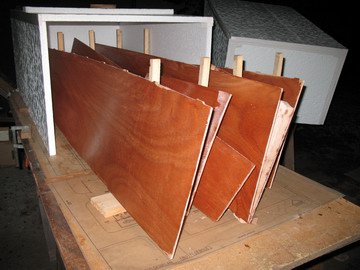

| A whole lot of seal-coated panels ready for the 'hot-box'. | Seat tops get re-inforcing pads for fixing of the inspection hatches glued on |

|

|

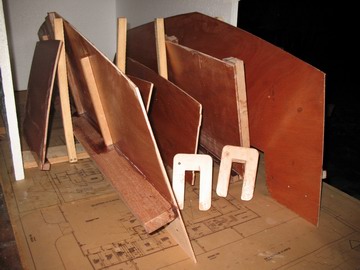

| Another batch of sealed and glued panels including dagger board case parts go in the oven.. | The recess for the lock is complete and the ss-flat bar is dry fitted. |

Previous page <> Next

Top of Page

Loading first page footer ... or Your browser does not support JavaScript

Loading second page footer ... or Your browser does not support JavaScript